Brandonite® is a patented family of composite materials, specifically composite polymers, designed to replace metal, plastic, or rubber. This family of composite materials is perfect for a broad number of applications, such as:

Brandonite® is a patented family of composite materials, specifically composite polymers, designed to replace metal, plastic, or rubber. This family of composite materials is perfect for a broad number of applications, such as:

- aerospace

- aeronautics

- industrial manufacturing

- self-lubricating parts and materials

- automation equipment

- radiation shielding

- antimicrobial medical devices,

- coverings, and prosthetics

What's a Polymer? Isn't It Just Plastic? Brandonite® possibly even could be made antibacterial, if need be, for implanted medical devices.

A Thermoplastic Molecule

A Thermoplastic MoleculeYes and no. Per the Oxford Dictionaries, a polymer is:

In other words, all plastics are polymers, but not all polymers are plastics. So, what makes Brandonite® not plastic?

Firstly, the Oxford Dictionaries definition of polymer isn't quite clear.

About.com describes polymers much more clearly as:

"A polymer is chemical compound where molecules are bonded together in long repeating chains. These materials, polymers, have unique properties and can be tailored depending on their intended purpose." - http://composite.about.com/od/whatsacomposite/a/What-Is-A-Polymer.htm

That's what Brandonite® is. It's a family of compounds that can be tailored or imbued with unique properties, such as being self-lubricating for the lifetime of the part, to fit almost any application you desire.

Secondly, polymers can be made from natural, organic materials, like rubber or glass, or from synthetic, man-made materials. Polymers can comprise resins and epoxies, again organic or synthetic, and hence aren't all plastics.

This, too, is what Brandonite® is. It's a family of composite materials composed of resins and epoxies that can be blended in numerous ways to fit various applications -- from hardened, heavy high-gravity composites to softer, antimicrobial coverings for medical devices. By introducing different additives into the Brandonite®, such as:

- carbon-fiber

- fiberglass

- S-glass

- glass/plastic microspheres

- even metallic powders

Brandonite® can be made tough-as-steel or softer than rubber.

What is Brandonite® Used For?

Since Brandonite® is a polymer and can be tailored for so many different uses, it can be used in any application to replace metal, plastic, or rubber parts. The new Brandonite® parts last longer and are more durable than their predecessors as well, due to the compound's ability to be developed for its specific application. The new parts can be developed for better wear and tear, to bend or stretch and not break under certain stressors, to not scratch, to not dent, even maintain themselves with self-lubrication -- which means less maintenance and less potential downtime for your system, as it won't need to be halted to add oil or the like.

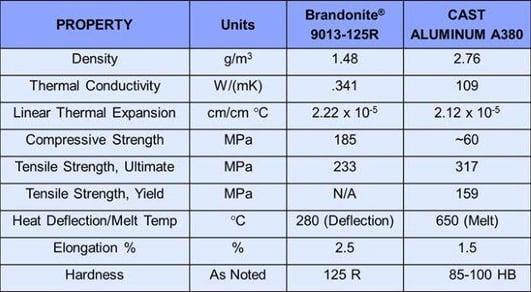

Brandonite®'s Properties vs. Aluminum

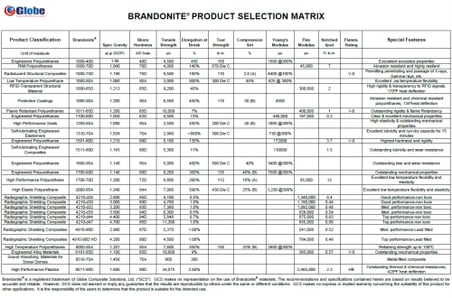

Which Brandonite® Do I Pick?

With all these different ways Brandonite® can be developed, how do I know which Brandonite® is right for me? Which Brandonite® is good for my application?

With all these different ways Brandonite® can be developed, how do I know which Brandonite® is right for me? Which Brandonite® is good for my application?

Not only can Globe Composite Solutions rapid prototype the perfect Brandonite® test part for your application, but we also have this handy chart detailing all the different types of Brandonite® in its family of materials that we've created thus far. Don't let this chart limit you however; Globe Composite is expert at researching and developing new, advanced materials all the time.

Still Have Questions?

Discover how Globe Composite Solutions' Brandonite® materials can work for you by starting a free consultation. We'll be sure to answer any gnawing questions you may have for free.